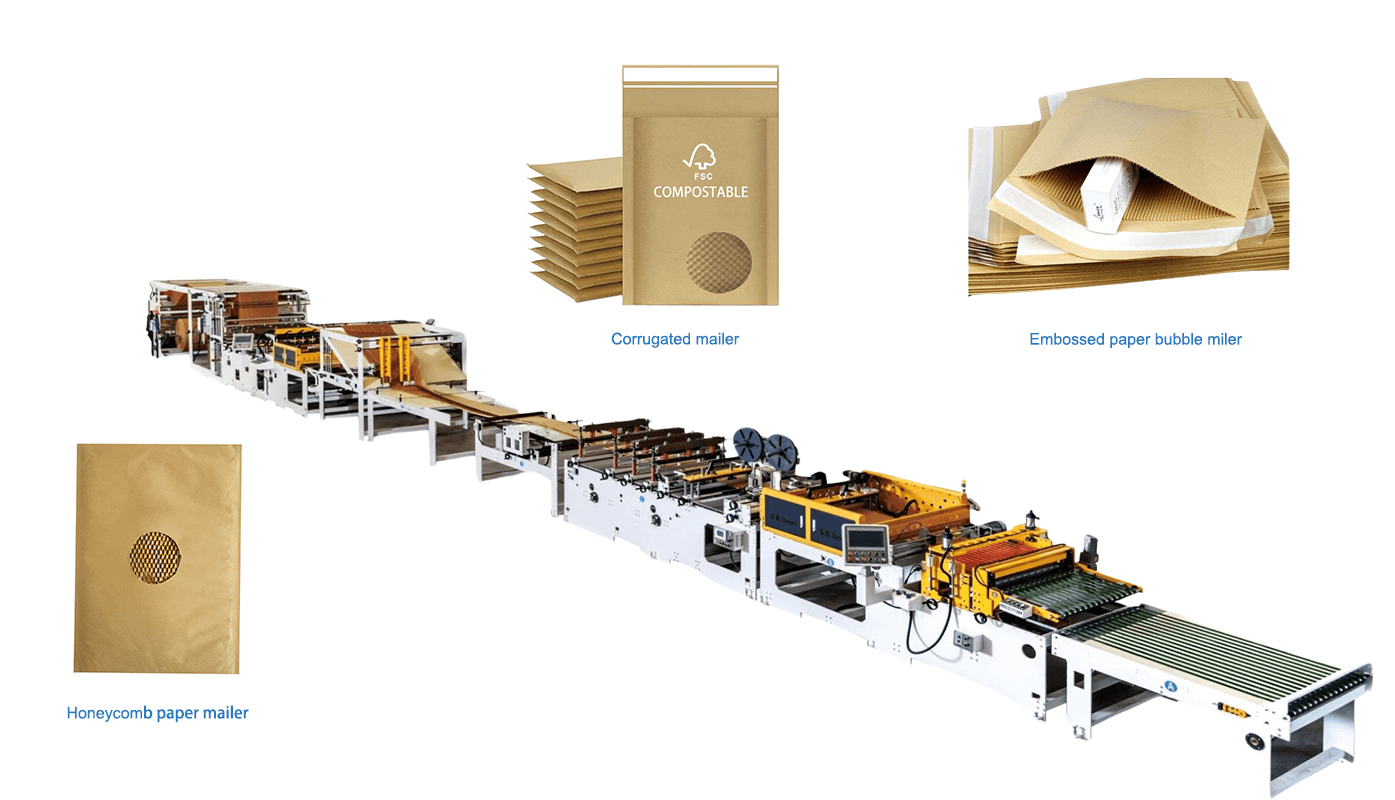

Honeycomb Envelope Manufacture Line

1) Our straight line design is simple in construction, ensuring easy installation and maintenance.

2) We use only the most advanced and reputable brand components for our pneumatic, electric and operating components, ensuring the highest level of performance and durability.

3) Our biodegradable, cost-effective, water-based adhesives create strong and clean sealing solutions for your packaging needs.

4) Our machines operate with a high degree of automation and intelligence, while still being eco-friendly and environmentally conscio

- Information

- Video

Machine Introduction

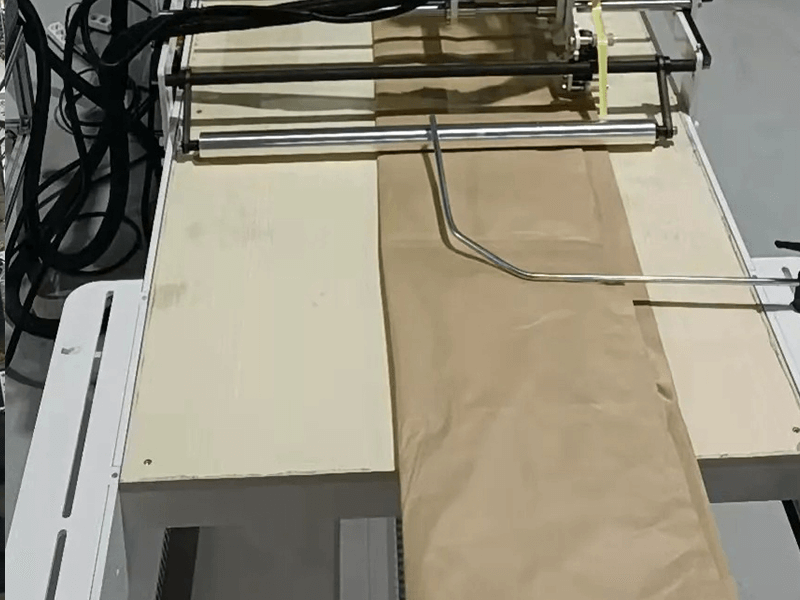

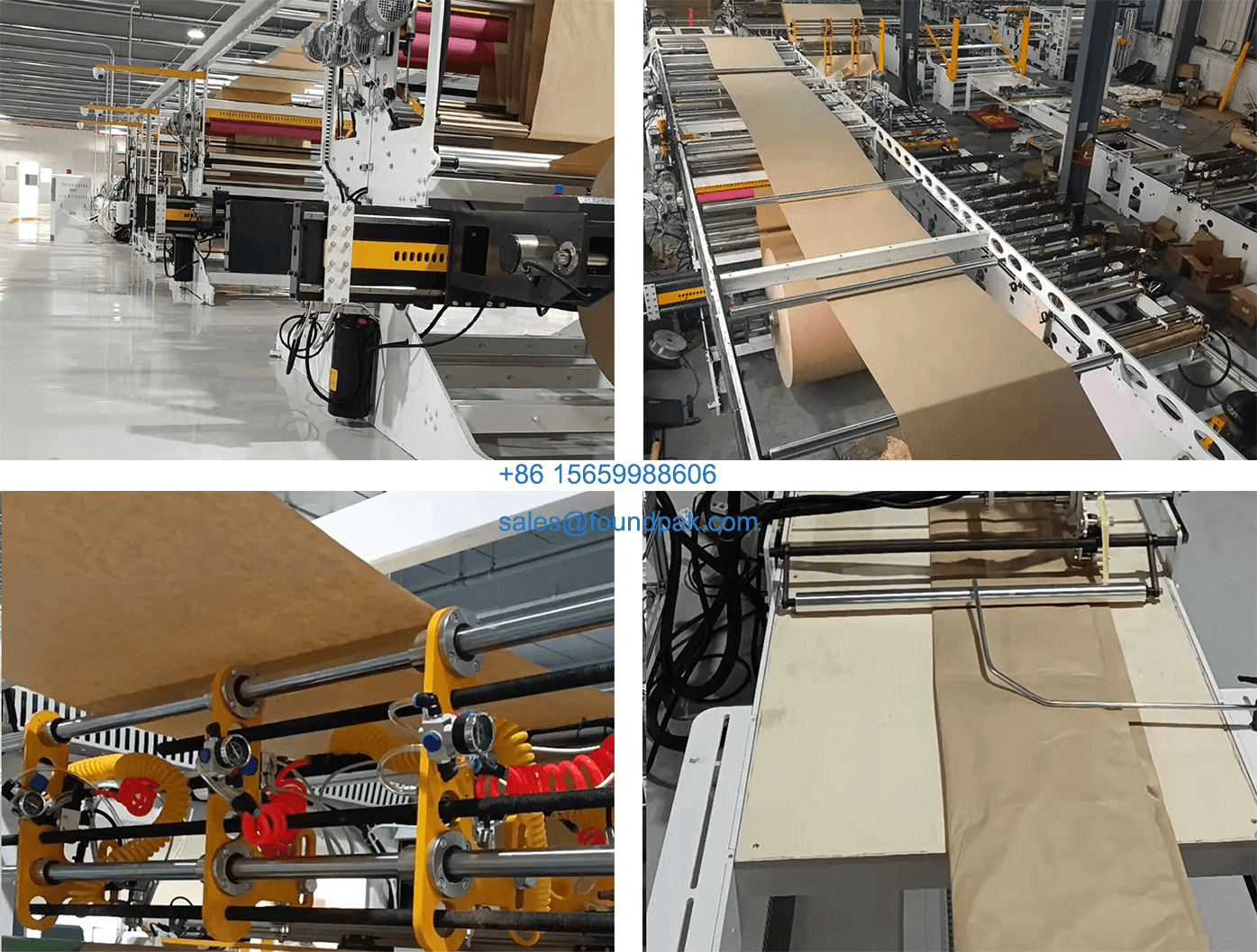

An Automatic Honeycomb Paper Mailer Bag Making Machine is specialized industrial equipment designed to manufacture honeycomb paper bags.

Honeycomb paper mailer bags can be customized in various sizes and logos, including patterns, so that the production can be regulated by the honeycomb paper bag making machine. The overall structure is simple, including paper feeding, cross-cutting and creasing machine bonding, and then output by the conveying system.

The overall operation is simple, the control panel is set up for background control, and the honeycomb paper bag is produced by loading kraft paper into the paper feeding system of the machine, and the finished bag is collected on the conveyor belt or stacking device for packaging or distribution.

Features

1, Adopts advanced motion control technology, from unwinding to cutting forming, are controlled by computer

2, Automatic Machine controlled by PLC and Inverter. Easy operation control panel.

3, Parameter setting effect immediately, tracked by electronic eyes, smooth and accurate.

4, Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release and pick up motors make production more productive.

5, It is very easy to load and unload products with air shafts in the rewinding and unwinding parts

Product Specification

| 1 | Material | Kraft Paper, Honeycomb paper |

| 2 | Unwinding Width | ≦1200 mm |

| 3 | Unwinding Diameter | ≦1200 mm |

| 4 | Speed of Making Bag | 30-50 units /min |

| 5 | Machine Speed | 60 m/min |

| 6 | Bag Width | ≦800 mm |

| 7 | Bag Length | 650 mm |

| 8 | Unwinding Part | Shaftless pneumatic Cone Jacking Device |

| 9 | Total Power | 28 KW |

| 10 | Machine Weight | 15.6 T |

| 11 | Appearance Color of Machine | White Plus Gray&Yellow |

| 12 | Machine Dimension | 31000mm*2200mm*2250mm |

| 13 | Air Supply | Auxiliary Device |

Our Factory

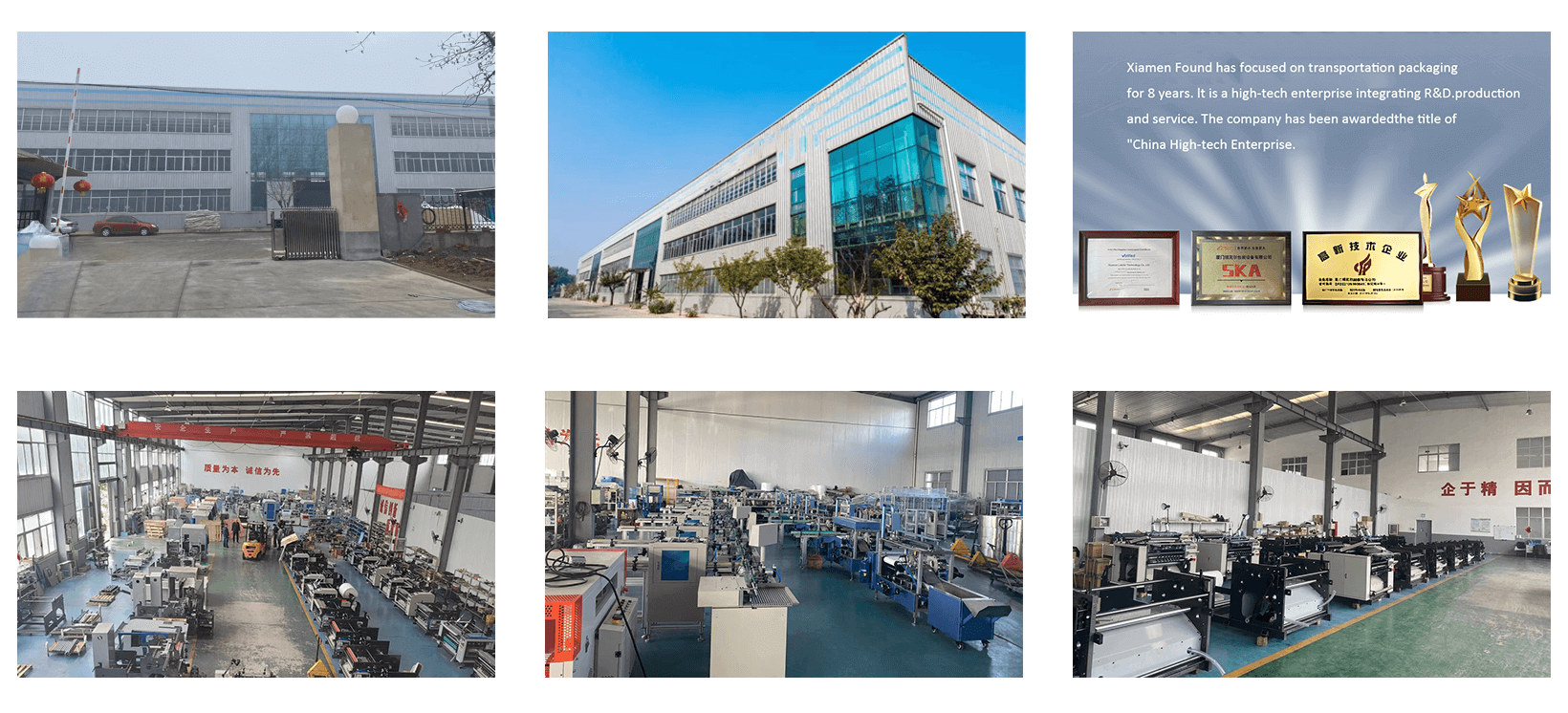

Precise sales, think what you think

By inspecting the global paper bag production status, comprehensively considering the suggestions of sustainable packaging industry, according to the actual needs of different customers, we design and produce a variety of configuration models, allowing customers to choose flexibly.

Excellent R& D management

We have an excellent R& D design team and excellent management talents in the packaging machine industry. We fully understand the actual needs of the packaging industry, ensuring that every piece of equipment we manufacture can be affirmed by customers and create greater benefits.

After-sale guarantee

Provide customers with comprehensive and timely after-sales service and a sense of service in the end.

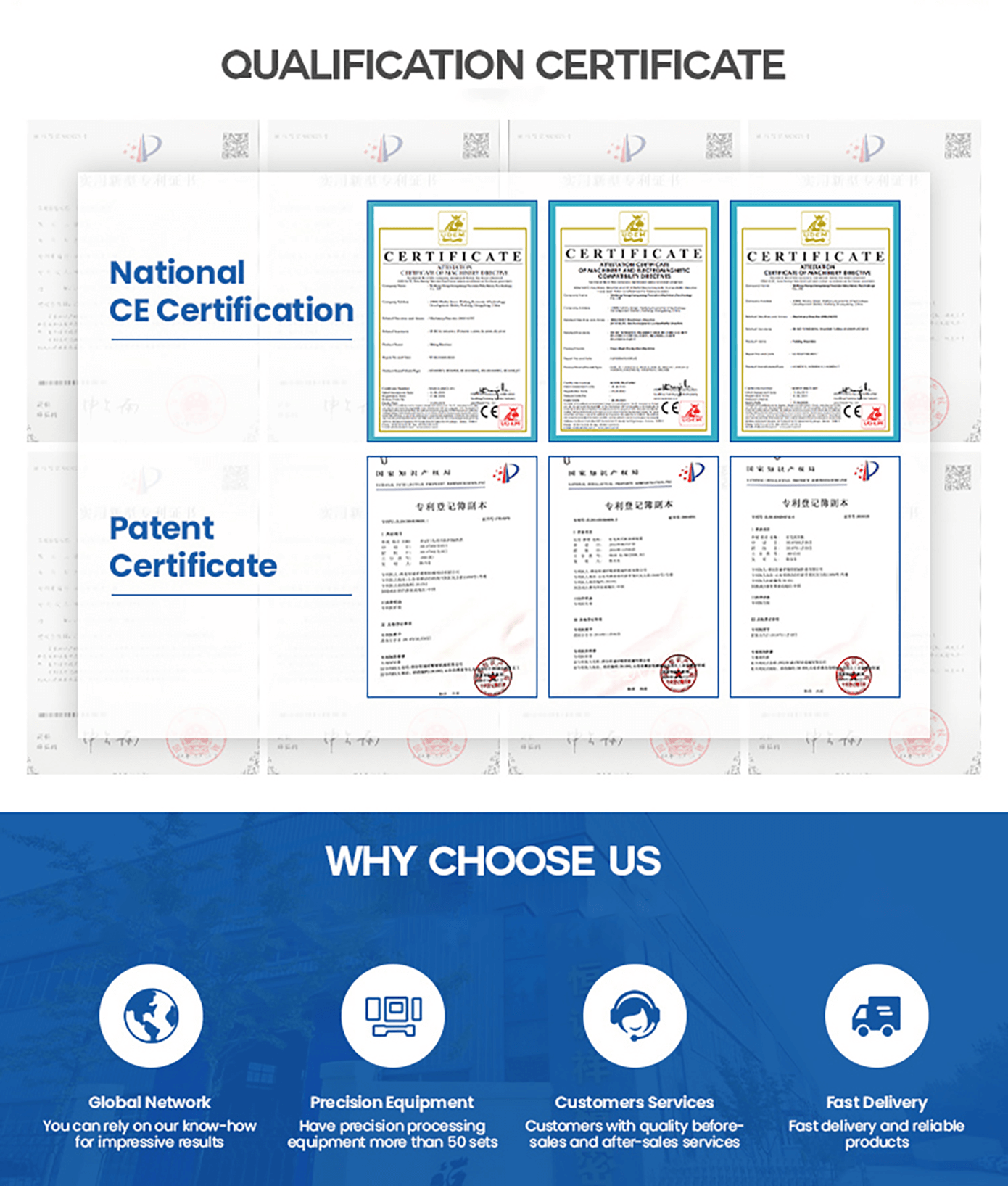

Certifications